With so many jobs to choose from, it can be intimidating to start a career in manufacturing and engineering. We’ve created this helpful guide to let you know what a Soldering Technician is, how much they earn, and what it takes to be one.

There aren’t too many demanding requirements to becoming a soldering technician, in fact, most companies just require GCSEs or minimal experience within a manufacturing or engineering environment. Becoming a soldering technician is a great way to enter into the electronics and manufacturing industry and progress into specialised roles within the industry.

Soldering Technician Job Description

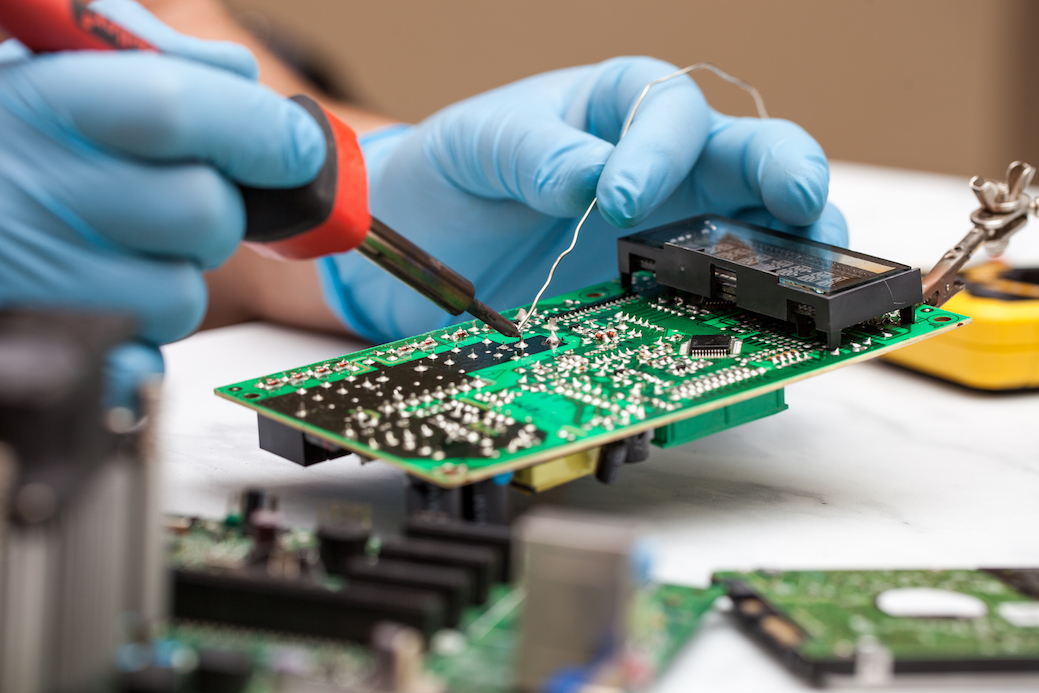

Working as part of a production line using small handheld tools, Soldering Technicians assemble circuit boards for electronic equipment. Following diagrams carefully and using a steady hand, Soldering Technicians specialise in the application of heat to low melting point metals to establish joins and connections.

Soldering Technicians use a variety of tools general to manufacturing electronics, aside from a soldering iron, such as side cutters, pliers, and crimp tools. Other roles of a Soldering Technician include:

- Repairing circuit boards.

- Cutting components to fit the board.

- Maintaining stock levels using a computerised system to ensure all needed equipment and materials are available.

- Testing finished boards to check functionality.

- Following technical drawings carefully.

Soldering Technician Skills

Naturally, it takes great skill to perform this exacting role reliant on accuracy. Here are some of the skills required of the role:

- Attention to Detail – Soldering Technicians need to be able to work quickly and accurately, creating precise replicas of technical drawings.

- Nimble Fingers – It is important that Soldering Technicians are dexterous and nimble, able to use small tools with great care to perform detailed work.

- Understanding Technical Drawings – Soldering Technicians must follow specific diagrams with certain requirements; it is imperative Soldering Technicians look for details.

- Hand-eye Coordination – Precision is paramount when soldering or using handheld tools on small components or boards.

- Quality Service – Many employers pride themselves on great quality of service and consistency; Soldering Technicians should also have these values and focus on excellence.

- IT Skills – It is likely Soldering Technicians evaluate their own stock levels, often using computerised systems to record levels.

Soldering Technician Qualifications

Most employers seeking Soldering Technicians do not ask for any specific qualifications, however, a minimum of 4 GCSEs is usually standard (in English, Maths, and engineering or science subject preferably).

Candidates with proven skills in soldering are more attractive to employers, for example, those with intermediate or advanced level apprenticeships are especially desirable. Alternatively, experience in a manufacturing or engineering environment is sure to go a long way in making a candidate stand out.

Training is always available, be it through the employer or externally. Even completing a short course on soldering could prove competency to work as a Soldering Technician, and many employers would be happy to accommodate further learning. Training in working in electronics would cover basic production line skills, from introducing tools and components to essential health and safety.

Generally, lacking experience in soldering is not a drawback, as long as candidates are willing to learn and keen to develop skills.

Soldering Technician Salary

Depending on the job advertisement and candidate experience, a Soldering Technician will most likely be salaried, otherwise occasionally paid between minimum wage and £10 an hour.

The starting salary for a Soldering Technician usually varies between £17,000-£19,000, but with experience this may increase to £20,500-£23,500. Senior Soldering Technicians can earn up to £26,000-£29,000. There are progression opportunities for Soldering Technicians which may be reflected in salary, including possible development to Manufacturing Engineer, Quality Assurance Technician or even Manufacturing Supervisor.

Soldering Technicians usually work up to 40 hours a week, however they may be required to do early morning starts. Overtime may be available too.

These figures are intended as a guide only.

Tips for Becoming a Soldering Technician

As mentioned above, there aren’t usually requirements concerning qualifications for becoming a Soldering Technician; therefore, experience and eagerness to learn are highly valued. Gaining experience in a manufacturing or electronics environment can be beneficial to candidates, even if it is only for a short period of time. Equally, having an understanding of basic health and safety or tools and components can help place a candidate above the rest.

Completing a relevant course or learning in free time is one way candidates can impress employers, further their own understanding, and display eagerness. Companies will be searching for keen candidates showing willingness, competency, and precision. Training will be involved in this role; therefore, employers will be looking for candidates that will make the most of this opportunity to benefit both the company and themselves.

If you believe you have the skills and drive to be a Soldering Technician, why not contact our team of recruitment specialists at BMR Solutions to see how we can help you?

Soldering Technician Opportunities with BMR Solutions

If you are interested in becoming a Soldering Technician, speak to one of our recruitment specialists at BMR Solutions today. We constantly advertise jobs from a variety of disciplines within engineering and manufacturing industries and love to help others find their dream job. Take a look at some of our jobs – we often have vacancies for Soldering Technicians.

With over 30 years’ experience in recruitment, we pride ourselves on finding the perfect fit, for both candidates and employers. Contact us and find out how we can help you with your career.